For the realization of a novel frequency comb technology, a research group from the Institute of Photonics at the Vienna University of Technology relied on flip chip and die bonding equipment from Finetech.

The Institute of Photonics at the Vienna University of Technology is a leader in the field of fundamental research on the generation of ultrashort high-intensity laser pulses, terahertz pulses and the realization of nano-photonic devices and their applications.

One research focus is on quantum cascade lasers (QCLs). These are compact and efficient radiation sources for the infrared and THz spectral range. Since these lasers have a broad emission spectrum, it is even possible to directly generate frequency combs, which are ideal for use in

high-resolution spectroscopy and metrology.

As part of the research on on-chip THz frequency combs, terahertz quantum cascade

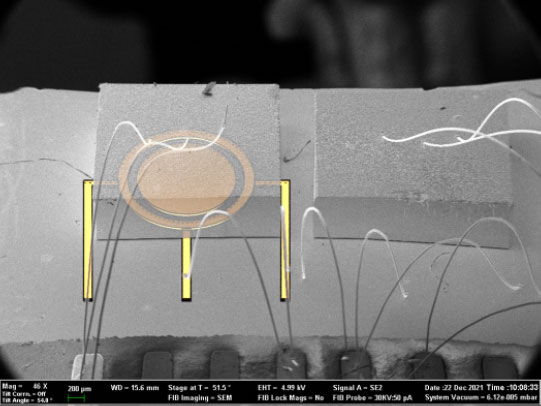

lasers in the form of a ring resonator should now be combined with established silicon photonics for the first time to lay the foundation for use in numerous new fields of application.

To do this, the researchers successfully used a tabletop die bonder from Finetech.

Quantum cascade lasers (QCLs) as terahertz radiation sources.

Terahertz radiation has many potential applications. Besides spectroscopy, these include sensor technology, imaging and communication. Air monitoring with gas sensors, body scanners at airports or fast 6G data communication are just a few keywords.

However, developing efficient and compact terahertz sources has long been a challenge. Conventional methods for generating terahertz radiation, such as using femtosecond lasers, are limited in terms of power, bandwidth and efficiency.

Terahertz QCLs are lasers based on III-V semiconductor nanostructures that operate on intersubband transitions in quantum wells, enabling tunable emission wavelengths between 1 and 5 THz. As on-chip light sources, they simultaneously offer high output power, spectral control, and compact design, making them ideal candidates for portable, high-precision spectroscopic applications.

III-V THz QCL meets Silicon Photonics

Now, the Institute of Photonics at TU Wien is researching to further improve the performance, efficiency and applications of terahertz QCLs, e.g., by using new materials, geometries and integration with other platforms.

Ring resonators are particularly promising in this respect. The underlying physics of light propagation in a ring-shaped resonator leads to a high light confinement in the laser geometry. The resulting increased interaction between light and laser material leads to an efficient formation of frequency combs. Furthermore, the low radiation losses of ring resonators compared to other geometries result in lower laser threshold currents as well as lower drive currents, which leads to reduced heat dissipation of the devices (important for continuous wave high power operation).

In the study in question, the advantages of ring-shaped THz QCLs should now be combined with established silicon photonics for the first time. This would enable arbitrary THz circuit configurations such as source-waveguide-detector systems or designs with fast modulators, since plasmonic or low-loss Si waveguides can be used.

Efficient, high-power radiation sources operating at room temperature, with waveguides, detectors or modulators integrated on the same chip, would also open up countless possibilities towards lab-on-a-chip systems, e.g. for gas sensing.

High precision flip chip bonder sought and found

Due to the small size of the devices, a direct wire bonding technique for electrical contacting was not possible. And the wafer-to-wafer bonder available at the Institute of Photonics was simply not capable of handling these structures reliably either, since precise alignment of the ring to the Si chip was required.

Therefore, those responsible went in search of a flip-chip bonder that was up to the task.

Goal of the study impressively achieved

And word of the FINEPLACER® lambda’s simple and intuitive operation, rapid readiness for use, accuracy and versatility quickly spread throughout the institute. Other research groups have long been using Finetech’s system for their own photonics research projects.